Hey there! I'm a supplier of explosive clad plates, and I've been in this industry for quite a while. Over the years, I've seen firsthand how crucial the bonding strength of explosive clad plates is. It can make or break a project, so understanding the factors that affect it is super important. In this blog post, I'll share with you what I've learned about the factors that influence the bonding strength of explosive clad plates.

1. Material Properties

First off, let's talk about the materials themselves. The properties of the base metal and the cladding metal play a huge role in the bonding strength.

Chemical Composition

The chemical composition of the metals is a key factor. Different elements can react differently during the explosive cladding process. For example, some elements might form intermetallic compounds at the interface between the base and cladding metals. These intermetallic compounds can either strengthen or weaken the bond, depending on their nature.

If the metals have a high affinity for each other, they're more likely to form a strong bond. On the other hand, if there are elements that create brittle intermetallic phases, it can reduce the bonding strength. For instance, some metals might form hard and brittle compounds that are prone to cracking under stress.

Mechanical Properties

The mechanical properties of the metals, such as hardness, ductility, and strength, also matter. If the base metal and the cladding metal have very different mechanical properties, it can create stress concentrations at the interface during the cladding process. This can lead to a weaker bond.

For example, if the cladding metal is much harder than the base metal, it might not deform as easily during the explosive impact. This can result in incomplete bonding or the formation of voids at the interface. On the contrary, if the metals have similar mechanical properties, they're more likely to deform together in a coordinated way, leading to a stronger bond.

2. Surface Preparation

The surface condition of the metals before the explosive cladding process is critical. A clean and properly prepared surface can significantly improve the bonding strength.

Cleaning

Any contaminants on the surface of the metals, such as oil, grease, rust, or dirt, can act as barriers to bonding. These contaminants can prevent the direct contact between the base and cladding metals, reducing the bonding strength.

Before the cladding process, we need to thoroughly clean the surfaces of both the base and cladding metals. This can be done using various methods, such as chemical cleaning, mechanical cleaning, or a combination of both. Chemical cleaning involves using solvents or acids to remove contaminants, while mechanical cleaning can include grinding, sandblasting, or wire brushing.

Surface Roughness

The surface roughness of the metals also affects the bonding strength. A certain degree of surface roughness can increase the contact area between the base and cladding metals, promoting better bonding. However, if the surface is too rough, it can trap air or contaminants during the cladding process, which can weaken the bond.

We usually aim for an optimal surface roughness that allows for good contact between the metals without introducing too many defects. This can be achieved through careful control of the surface preparation process.

3. Explosive Parameters

The explosive used in the cladding process and its parameters have a significant impact on the bonding strength.

Explosive Type

Different types of explosives have different energy release rates and detonation velocities. The choice of explosive depends on the specific requirements of the cladding process, such as the thickness and type of metals being clad.

For example, high - energy explosives can generate a more intense shock wave, which can be beneficial for bonding thicker or harder metals. However, using an explosive with too high an energy can also cause excessive deformation or damage to the metals, reducing the bonding quality.

Explosive Charge Density

The charge density of the explosive, which is the amount of explosive per unit area, is another important parameter. A higher charge density generally results in a stronger shock wave, which can improve the bonding strength. However, if the charge density is too high, it can cause excessive melting or vaporization of the metals at the interface, leading to the formation of defects.

We need to carefully adjust the explosive charge density based on the properties of the metals and the desired bonding strength. This often requires some trial - and - error to find the optimal value.

4. Process Parameters

Apart from the explosive parameters, other process parameters also affect the bonding strength.

Stand - off Distance

The stand - off distance is the gap between the base metal and the cladding metal before the explosive detonation. A proper stand - off distance is necessary for the formation of a strong bond.

If the stand - off distance is too small, the cladding metal might not have enough space to accelerate and deform properly, resulting in incomplete bonding. On the other hand, if the stand - off distance is too large, the shock wave energy might be dissipated before it reaches the metals, also leading to a weak bond.

Impact Angle

The impact angle between the cladding metal and the base metal during the explosive cladding process is also crucial. The impact angle affects the way the metals deform and interact at the interface.

An optimal impact angle can promote the formation of a wavy interface, which can increase the bonding strength by increasing the contact area and mechanical interlocking between the metals. However, if the impact angle is too large or too small, it can lead to poor bonding or the formation of defects.

5. Post - Treatment

After the explosive cladding process, post - treatment can also have an impact on the bonding strength.

Heat Treatment

Heat treatment can be used to relieve residual stresses in the clad plate and improve the bonding strength. By heating the clad plate to a certain temperature and then cooling it at a controlled rate, we can reduce the internal stresses that were generated during the explosive cladding process.

Heat treatment can also promote the diffusion of atoms at the interface between the base and cladding metals, which can strengthen the bond. However, if the heat treatment parameters are not properly controlled, it can also cause the formation of unwanted phases or the degradation of the bonding strength.

Machining and Finishing

Machining and finishing operations, such as cutting, grinding, or polishing, can also affect the bonding strength. If these operations are not carried out carefully, they can introduce new stresses or damage the bond at the interface.

For example, excessive grinding can generate heat, which can cause thermal stress and potentially weaken the bond. We need to use appropriate machining and finishing techniques to ensure that the bonding strength of the clad plate is maintained.

Conclusion

As you can see, there are many factors that affect the bonding strength of explosive clad plates. From the material properties and surface preparation to the explosive and process parameters, and even the post - treatment, every step in the process plays a crucial role.

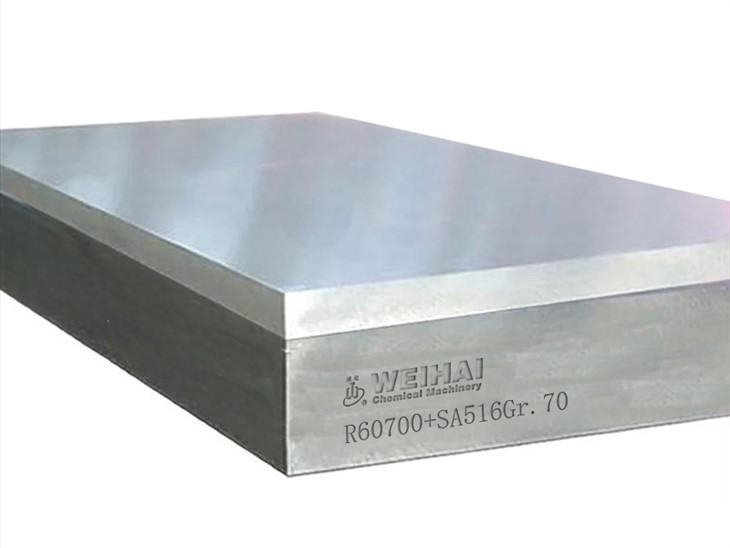

At our company, we pay close attention to all these factors to ensure that we produce high - quality explosive clad plates with strong bonding strength. We offer a wide range of explosive clad plates, including Nickel-base Steel Clad Plate, Other Alloy Clad Plate, and Titanium Steel Clad Plate.

If you're in the market for explosive clad plates, or if you have any questions about our products, feel free to reach out to us. We're always happy to discuss your needs and provide you with the best solutions. Let's work together to make your projects a success!

References

- Johnson, R. A. (2015). Explosive Cladding Technology: A Review. Journal of Materials Engineering and Performance, 24(8), 2923 - 2934.

- Smith, B. C., & Jones, D. E. (2018). Factors Affecting the Bond Strength of Metal Clad Plates Produced by Explosive Welding. Welding Journal, 97(5), 123 - 130.

- Brown, S. M. (2020). Optimization of Explosive Cladding Process Parameters for Enhanced Bonding Strength. International Journal of Advanced Manufacturing Technology, 107(9 - 12), 3215 - 3224.