Hey there! As a supplier of Other Alloy Clad Plate, I often get asked about the difference between Other Alloy Clad Plate and stainless - clad plate. So, I thought I'd sit down and write this blog to clear things up.

Let's start with the basics. Clad plates are composite materials made by bonding two or more different metals together. This combination allows us to take advantage of the unique properties of each metal, creating a product that's stronger, more corrosion - resistant, or better suited to specific applications than a single metal could be on its own.

Stainless - Clad Plate

Stainless - clad plate is probably the more well - known of the two. It consists of a base layer, usually made of carbon steel, and a cladding layer of stainless steel. Stainless steel is famous for its excellent corrosion resistance, which comes from the chromium in its composition. When chromium reacts with oxygen in the air, it forms a thin, invisible layer of chromium oxide on the surface of the steel. This layer acts as a shield, preventing further oxidation and corrosion.

One of the big advantages of stainless - clad plate is its cost - effectiveness. Carbon steel is relatively inexpensive, and by using it as the base layer, we can reduce the amount of stainless steel needed. At the same time, we still get the corrosion - resistant benefits of the stainless steel on the surface. Stainless - clad plates are widely used in industries like food processing, chemical manufacturing, and architecture. For example, in food processing plants, the corrosion - resistant surface of the stainless - clad plate ensures that there's no contamination of the food products.

Other Alloy Clad Plate

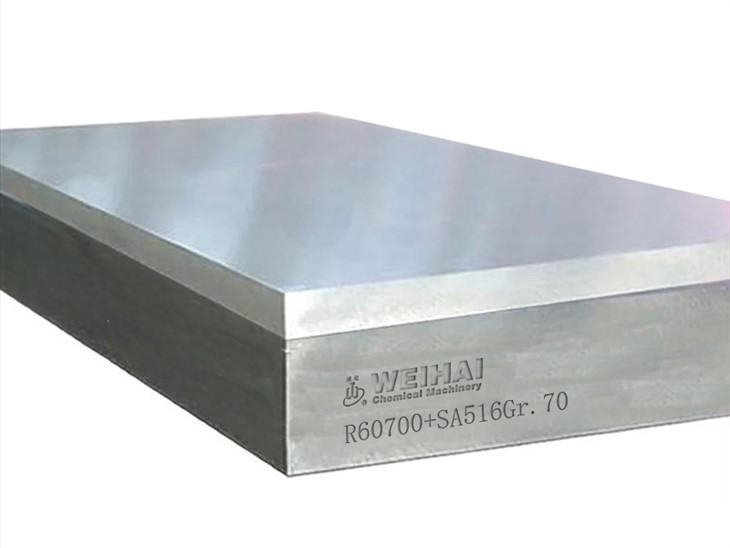

Now, let's talk about Other Alloy Clad Plate. As the name suggests, this type of clad plate uses alloys other than stainless steel as the cladding layer. These alloys can include titanium, nickel, copper, and many others. Each of these alloys has its own unique set of properties, which makes Other Alloy Clad Plate suitable for a wide range of specialized applications.

For instance, Titanium Steel Clad Plate combines the high strength and low weight of titanium with the cost - effectiveness and good mechanical properties of steel. Titanium is extremely corrosion - resistant, especially in harsh environments like seawater. So, Titanium Steel Clad Plate is often used in the marine industry, for things like shipbuilding and offshore platforms.

Another example is the use of nickel - based alloys in Other Alloy Clad Plate. Nickel alloys have excellent heat resistance and can withstand high temperatures without losing their strength. This makes them ideal for applications in the aerospace and power generation industries, where components need to operate under extreme conditions.

Key Differences

1. Corrosion Resistance

While stainless - clad plate offers good general corrosion resistance, Other Alloy Clad Plate can provide even better performance in specific environments. For example, titanium - clad plates are highly resistant to corrosion in seawater, acidic solutions, and chloride - rich environments. This is because titanium forms a very stable oxide layer that is more resistant to breakdown compared to the chromium oxide layer on stainless steel. So, if you're working in a marine or chemical environment where the corrosion is particularly aggressive, Other Alloy Clad Plate might be the better choice.

2. Mechanical Properties

The mechanical properties of Other Alloy Clad Plate can vary widely depending on the alloy used in the cladding. Some alloys, like titanium, have a high strength - to - weight ratio. This means that a Titanium Steel Clad Plate can be lighter than a stainless - clad plate of the same strength. On the other hand, stainless - clad plates generally have more consistent mechanical properties across different applications, as stainless steel has well - known and predictable behavior.

3. Cost

Stainless - clad plate is usually more cost - effective in general applications. The widespread availability of stainless steel and carbon steel keeps the prices relatively low. However, when it comes to specialized applications that require the unique properties of other alloys, the cost of Other Alloy Clad Plate might be justified. For example, in the aerospace industry, where performance is critical, the higher cost of nickel - based Other Alloy Clad Plate is often acceptable.

4. Application Range

Stainless - clad plate has a broad range of applications in common industries due to its good all - around performance. It's a go - to choice for many standard applications where corrosion resistance and moderate strength are required. Other Alloy Clad Plate, on the other hand, is more focused on specialized applications. For example, Two Sides Clad Plate, a type of Other Alloy Clad Plate, can be used in applications where both sides of the plate need to have different properties, such as in some high - tech electronic devices.

Why Choose Our Other Alloy Clad Plate

As a supplier of Other Alloy Clad Plate, I'm really proud of the products we offer. We use state - of - the - art manufacturing processes to ensure that the bonding between the base layer and the cladding layer is strong and reliable. This means that our clad plates have excellent performance and long service lives.

We also have a team of experts who can help you choose the right type of Other Alloy Clad Plate for your specific application. Whether you're in the marine, aerospace, or chemical industry, we can provide you with the best solution based on your requirements.

If you're looking for high - quality Other Alloy Clad Plate for your project, I'd encourage you to get in touch with us. We're always happy to have a chat about your needs and see how we can help. Whether it's about the technical details, pricing, or delivery options, we're here to assist you every step of the way.

Conclusion

In conclusion, both stainless - clad plate and Other Alloy Clad Plate have their own strengths and weaknesses. Stainless - clad plate is a great choice for general applications where cost - effectiveness and good all - around performance are important. Other Alloy Clad Plate, on the other hand, shines in specialized applications where the unique properties of other alloys are required.

If you're still not sure which type of clad plate is right for you, don't hesitate to reach out. We can work together to figure out the best solution for your specific situation. Looking forward to hearing from you and starting a great business relationship!

References

- ASM Handbook Committee. (2004). ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection. ASM International.

- Dupont, J. N., & Marder, A. R. (2001). Welding of stainless steels. ASM International.