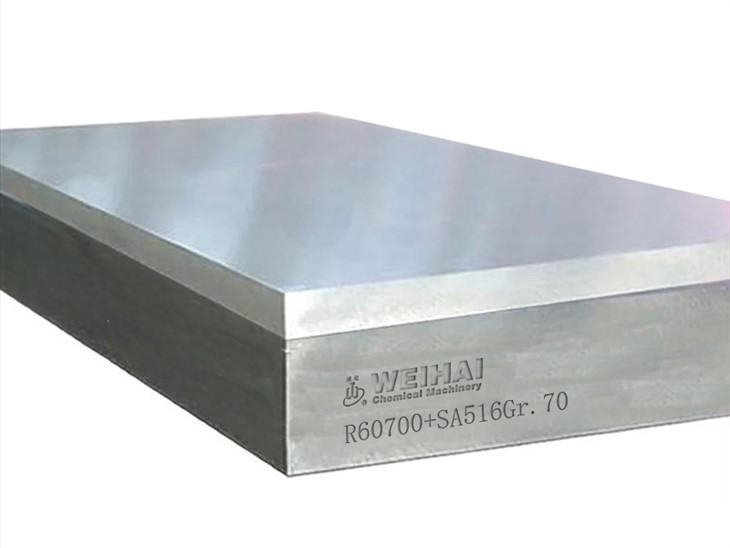

In the vast and diverse food industry, the choice of materials is of paramount importance. Among the various materials available, Nickel - base Steel Clad Plate has emerged as a remarkable option, offering a unique combination of properties that make it highly suitable for a wide range of applications. As a supplier of Nickel - base Steel Clad Plate, I am excited to delve into the details of its applications in the food industry.

1. Corrosion Resistance: A Key Requirement in Food Processing

One of the most critical factors in the food industry is corrosion resistance. Food products often contain acids, salts, and other corrosive substances that can damage traditional materials over time. Nickel - base Steel Clad Plate provides excellent corrosion resistance due to the presence of nickel in the cladding layer. Nickel has a high resistance to oxidation and can form a passive oxide film on its surface, which acts as a barrier against corrosive agents.

For example, in dairy processing plants, where milk and other dairy products are handled, the equipment is constantly exposed to lactic acid and other acidic components. Nickel - base Steel Clad Plate can withstand these corrosive environments, ensuring the longevity of the equipment and preventing contamination of the food products. Similarly, in the production of fruit juices and soft drinks, which may contain citric acid and other organic acids, this material can resist corrosion and maintain the integrity of the processing equipment.

2. Hygiene and Cleanability

Hygiene is a top priority in the food industry. Any material used in food processing and storage must be easy to clean and maintain to prevent the growth of bacteria and other microorganisms. Nickel - base Steel Clad Plate has a smooth and non - porous surface, which makes it difficult for bacteria to adhere to. This property, combined with its corrosion resistance, allows for easy cleaning and disinfection of the equipment.

In food processing plants, the surfaces of tanks, pipes, and other equipment are regularly cleaned using high - pressure water, detergents, and sanitizers. The smooth surface of Nickel - base Steel Clad Plate ensures that these cleaning agents can effectively remove any residues or contaminants. Moreover, the material does not absorb moisture or odors, which further contributes to maintaining a hygienic environment.

3. Strength and Durability

Food processing equipment often operates under high pressure and temperature conditions. It needs to be strong enough to withstand these harsh operating conditions without deforming or failing. Nickel - base Steel Clad Plate combines the high strength of steel with the corrosion - resistant properties of nickel. The steel core provides the necessary structural support, while the nickel cladding layer protects the core from corrosion.

For instance, in the brewing industry, large fermentation tanks are used to produce beer. These tanks are subjected to high pressures and temperatures during the fermentation process. Nickel - base Steel Clad Plate can withstand these conditions, ensuring the safe and efficient operation of the tanks. Additionally, in the meat processing industry, where heavy machinery is used for cutting, grinding, and packaging, the strength and durability of this material are essential to prevent equipment breakdowns and ensure continuous production.

4. Applications in Different Segments of the Food Industry

a. Food Processing Equipment

As mentioned earlier, Nickel - base Steel Clad Plate is widely used in the manufacturing of food processing equipment such as tanks, pipes, heat exchangers, and mixers. In a large - scale food processing plant, these components are crucial for the efficient production of food products. For example, heat exchangers are used to transfer heat between different food products or between a food product and a heating or cooling medium. The corrosion resistance of Nickel - base Steel Clad Plate ensures that the heat transfer process is not affected by corrosion, maintaining the quality and safety of the food.

b. Food Storage

In the food storage sector, Nickel - base Steel Clad Plate is used to construct storage silos and containers. These storage facilities need to protect the food products from external factors such as moisture, oxygen, and pests. The corrosion resistance and durability of this material make it an ideal choice for long - term food storage. For example, in the storage of grains and cereals, silos made of Nickel - base Steel Clad Plate can prevent the entry of moisture and pests, preserving the quality of the stored food.

c. Food Packaging

Although not as common as in processing and storage, Nickel - base Steel Clad Plate also has potential applications in food packaging. Some high - end food products may require packaging materials that can provide a high level of protection against oxygen and moisture. The corrosion resistance and barrier properties of this material could be utilized to develop innovative packaging solutions.

5. Comparison with Other Materials

When compared to other materials commonly used in the food industry, Nickel - base Steel Clad Plate offers several advantages.

- Stainless Steel: While stainless steel is also widely used in the food industry, Nickel - base Steel Clad Plate can provide better corrosion resistance in certain aggressive environments. For example, in the presence of high - concentration acids or salts, the nickel cladding layer of the clad plate can offer superior protection compared to the chromium - based passive film on stainless steel.

- Aluminum: Aluminum is lightweight and has good thermal conductivity. However, it is more prone to corrosion in acidic and alkaline environments. Nickel - base Steel Clad Plate, on the other hand, can resist a wider range of corrosive substances, making it more suitable for applications where corrosion is a major concern.

6. Other Related Alloy Clad Plates

In addition to Nickel - base Steel Clad Plate, there are other alloy clad plates that may also find applications in the food industry. You can explore more about Other Alloy Clad Plate. For example, Titanium Steel Clad Plate offers excellent corrosion resistance and high strength - to - weight ratio. It can be used in applications where a combination of these properties is required. Another option is the Two Sides Clad Plate, which can provide different properties on each side, allowing for more customized solutions in the food industry.

7. Conclusion and Call to Action

In conclusion, Nickel - base Steel Clad Plate offers a wide range of benefits for the food industry, including corrosion resistance, hygiene, strength, and durability. Its applications span across various segments of the food industry, from processing and storage to potential packaging solutions.

If you are in the food industry and are looking for high - quality materials for your equipment or storage facilities, I encourage you to consider Nickel - base Steel Clad Plate. As a supplier, we are committed to providing you with the best products and services. We can work with you to understand your specific requirements and offer customized solutions. Whether you need a small - scale component or a large - scale installation, we have the expertise and resources to meet your needs. Please feel free to contact us to start a procurement discussion and explore how Nickel - base Steel Clad Plate can enhance the efficiency and safety of your food operations.

References

- ASM Handbook Committee. (2004). ASM Handbook Volume 13A: Corrosion: Fundamentals, Testing, and Protection. ASM International.

- Schubert, H. (2008). Food Process Engineering and Technology. Elsevier.

- Kirk - Othmer Encyclopedia of Chemical Technology. (2007). John Wiley & Sons.