Hey there! As a supplier of Two Sides Clad Plate, I'm super excited to share with you the different installation methods for these awesome plates. Two Sides Clad Plates are pretty cool because they combine the best features of two different materials, giving you a product that's strong, durable, and has all sorts of great properties.

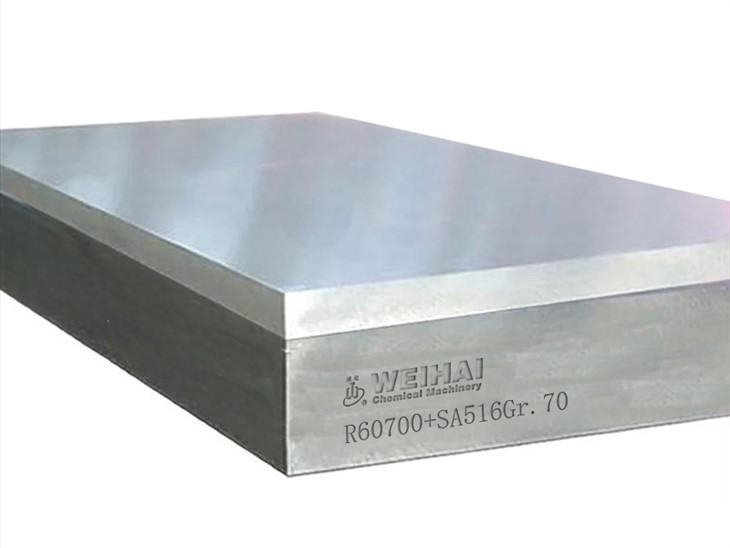

First off, let me give you a quick intro to what Two Sides Clad Plates are. These plates are made by bonding two different metals or alloys together, usually a base metal and a cladding metal. The base metal provides the structural strength, while the cladding metal offers additional benefits like corrosion resistance, wear resistance, or aesthetic appeal. We offer a variety of Two Sides Clad Plates, including Titanium Steel Clad Plate, Stainless Steel Clad Plate, and Other Alloy Clad Plate.

Now, let's dive into the installation methods. There are several ways to install Two Sides Clad Plates, and the choice of method depends on a few factors like the type of plate, the application, and the specific requirements of the project.

1. Welding Installation

Welding is one of the most common methods for installing Two Sides Clad Plates. It's a great option when you need a strong and permanent bond between the plates. There are a few different welding techniques that can be used:

Submerged Arc Welding (SAW)

SAW is a popular welding method for cladding plates. It involves creating an arc between a consumable electrode and the workpiece, with the arc being submerged in a layer of granular flux. This method is great because it provides a high deposition rate, which means you can weld large areas quickly. It also produces a high-quality weld with good mechanical properties. However, it requires a special welding machine and a bit of skill to operate.

Gas Tungsten Arc Welding (GTAW)

GTAW, also known as TIG welding, is another option for welding Two Sides Clad Plates. It uses a non-consumable tungsten electrode to create an arc, and a filler metal can be added if needed. GTAW is a precise welding method that produces a clean and high-quality weld. It's often used for thin cladding layers or when a high level of control is required. But it's a slower process compared to SAW and requires more skill to master.

Shielded Metal Arc Welding (SMAW)

SMAW, or stick welding, is a simple and versatile welding method. It uses a consumable electrode coated with a flux to create an arc. SMAW is easy to learn and can be used in a variety of environments. However, it has a lower deposition rate compared to SAW and GTAW, and the weld quality may not be as high.

When using welding to install Two Sides Clad Plates, it's important to follow the proper welding procedures and use the right welding materials. You also need to make sure the plates are properly prepared before welding, which includes cleaning the surfaces and removing any contaminants.

2. Mechanical Fastening

Mechanical fastening is another option for installing Two Sides Clad Plates. This method involves using bolts, screws, or rivets to attach the plates to the substrate. Mechanical fastening is a quick and easy way to install the plates, and it doesn't require any special welding equipment.

Bolting

Bolting is a common mechanical fastening method. It involves drilling holes in the plates and the substrate and then using bolts and nuts to secure them together. Bolting is a reliable method that can be easily disassembled if needed. However, it may not provide as strong a bond as welding, and there is a risk of the bolts loosening over time.

Riveting

Riveting is another mechanical fastening method. It involves using a rivet gun to insert a rivet through holes in the plates and the substrate and then deforming the end of the rivet to hold the plates in place. Riveting is a permanent fastening method that provides a strong bond. But it requires a special rivet gun and can be more difficult to install compared to bolting.

When using mechanical fastening, it's important to choose the right type and size of fasteners for the application. You also need to make sure the holes are properly aligned and the fasteners are tightened to the correct torque.

3. Adhesive Bonding

Adhesive bonding is a less common but still viable option for installing Two Sides Clad Plates. This method involves using an adhesive to bond the plates to the substrate. Adhesive bonding has several advantages, including the ability to bond dissimilar materials, the ability to distribute stress evenly, and the ability to provide a seal against moisture and chemicals.

There are several types of adhesives that can be used for bonding Two Sides Clad Plates, including epoxy adhesives, polyurethane adhesives, and acrylic adhesives. The choice of adhesive depends on the type of materials being bonded, the application, and the environmental conditions.

When using adhesive bonding, it's important to follow the manufacturer's instructions carefully. The surfaces of the plates and the substrate need to be properly cleaned and prepared before applying the adhesive. You also need to make sure the adhesive is applied evenly and that the plates are held in place until the adhesive cures.

Factors to Consider When Choosing an Installation Method

When choosing an installation method for Two Sides Clad Plates, there are several factors you need to consider:

Strength Requirements

The strength requirements of the application will determine which installation method is best. If you need a strong and permanent bond, welding may be the best option. If you need a temporary or easily removable bond, mechanical fastening or adhesive bonding may be more suitable.

Cost

The cost of the installation method is also an important factor. Welding can be more expensive due to the cost of the welding equipment and the labor required. Mechanical fastening and adhesive bonding are generally less expensive, but the cost of the fasteners or adhesives needs to be considered.

Environment

The environment in which the plates will be installed also needs to be considered. If the plates will be exposed to high temperatures, corrosive chemicals, or other harsh conditions, you need to choose an installation method that can withstand these conditions.

Aesthetics

If the appearance of the installation is important, you may need to choose an installation method that doesn't leave visible welds or fasteners. Adhesive bonding can be a good option in this case, as it provides a smooth and seamless finish.

In conclusion, there are several installation methods available for Two Sides Clad Plates, each with its own advantages and disadvantages. The choice of method depends on a variety of factors, including the strength requirements, cost, environment, and aesthetics of the application. As a supplier of Two Sides Clad Plates, we can help you choose the right installation method for your project and provide you with the necessary support and guidance.

If you're interested in purchasing Two Sides Clad Plates or have any questions about the installation methods, feel free to reach out to us. We're always happy to help and look forward to working with you on your next project.

References

- ASME Boiler and Pressure Vessel Code

- AWS D1.1/D1.1M: Structural Welding Code - Steel

- Manufacturer's specifications for Two Sides Clad Plates