As a supplier of Stainless Steel Clad Plate, I've witnessed firsthand the remarkable properties and wide - ranging applications of this material. One topic that constantly piques the interest of our clients is the effects of heat treatment on the bonding strength of stainless steel clad plate. In this blog, I'll delve into this subject in detail, exploring the science behind it and its practical implications.

Understanding Stainless Steel Clad Plate

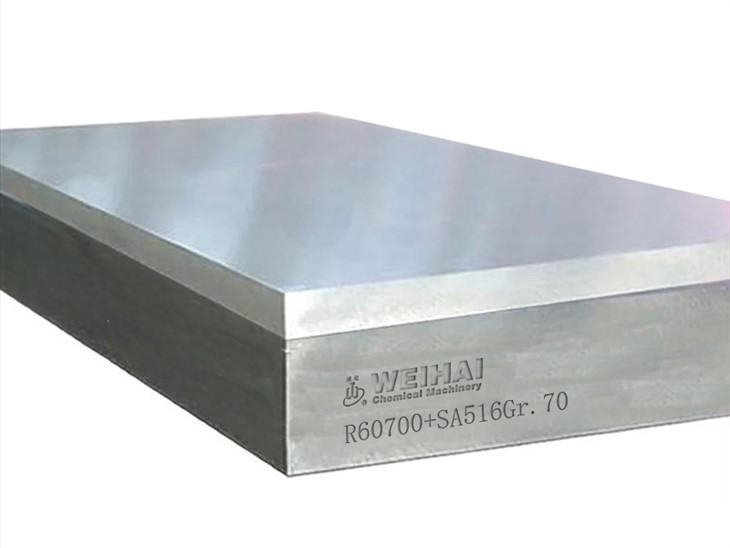

Before we discuss the impact of heat treatment, let's briefly understand what stainless steel clad plate is. A stainless steel clad plate consists of a base layer and a cladding layer. The base layer is typically made of carbon steel or low - alloy steel, which provides structural strength and cost - effectiveness. The cladding layer is stainless steel, offering excellent corrosion resistance, aesthetic appeal, and other beneficial properties. This combination makes stainless steel clad plate a popular choice in various industries, such as chemical processing, food processing, and construction.

You can find more information about our Stainless Steel Clad Plate on our website.

Bonding Mechanisms in Stainless Steel Clad Plate

The bonding between the base layer and the cladding layer in a stainless steel clad plate is crucial for its performance. There are different methods to achieve this bonding, such as explosive cladding, roll bonding, and diffusion bonding. In explosive cladding, a controlled explosive charge is used to force the two layers together at high speed, creating a metallurgical bond. Roll bonding involves passing the two layers through a rolling mill under high pressure, causing plastic deformation and bonding. Diffusion bonding relies on the diffusion of atoms across the interface at elevated temperatures and pressures.

Regardless of the bonding method, the quality of the bond is characterized by factors like bond strength, bond integrity, and the presence of intermetallic compounds. A strong bond ensures that the clad plate can withstand mechanical stresses, thermal cycling, and corrosive environments without delamination.

The Role of Heat Treatment

Heat treatment is a process that involves heating and cooling a material to alter its physical and mechanical properties. When it comes to stainless steel clad plate, heat treatment can have both positive and negative effects on the bonding strength.

Positive Effects of Heat Treatment

- Relief of Residual Stresses: During the manufacturing process, especially in explosive cladding, residual stresses are introduced into the clad plate. These stresses can potentially lead to cracking or delamination over time. Heat treatment at an appropriate temperature can relieve these residual stresses, improving the overall integrity of the bond. For example, a stress - relief annealing process can be carried out at a temperature range of 550 - 650°C for a certain period, depending on the thickness and composition of the clad plate.

- Improvement of Microstructure: Heat treatment can also modify the microstructure of the bond interface. By heating the clad plate to a specific temperature and then cooling it at a controlled rate, the formation of a more homogeneous and fine - grained microstructure can be promoted. This can enhance the diffusion of atoms across the interface, strengthening the bond. For instance, a solution annealing treatment followed by rapid quenching can result in a more uniform distribution of alloying elements at the interface, improving the bonding strength.

- Enhancement of Corrosion Resistance: In some cases, heat treatment can improve the corrosion resistance of the clad plate, which is indirectly related to the bonding strength. A well - heat - treated clad plate can form a more stable passive film on the stainless steel cladding layer, protecting the bond interface from corrosive attack. This helps to maintain the integrity of the bond over a longer period.

Negative Effects of Heat Treatment

- Formation of Intermetallic Compounds: One of the major concerns with heat treatment is the formation of intermetallic compounds at the bond interface. When the clad plate is heated to high temperatures for an extended period, elements from the base layer and the cladding layer can react to form intermetallic phases. These intermetallic compounds are often brittle and can reduce the bonding strength. For example, in a carbon steel - stainless steel clad plate, the formation of iron - chromium intermetallic compounds can occur at temperatures above 800°C, leading to a decrease in bond strength.

- Grain Growth: Excessive heat treatment can also cause grain growth in the base layer and the cladding layer. Coarse - grained microstructures are generally associated with lower mechanical properties, including reduced bonding strength. Grain growth can weaken the bond interface by reducing the number of grain boundaries available for atom diffusion and mechanical interlocking.

Factors Affecting the Impact of Heat Treatment

The effects of heat treatment on the bonding strength of stainless steel clad plate are influenced by several factors:

- Heat Treatment Parameters: The temperature, time, and cooling rate during heat treatment are critical. Higher temperatures and longer holding times increase the likelihood of intermetallic compound formation and grain growth. On the other hand, too low a temperature may not be effective in relieving residual stresses or improving the microstructure.

- Composition of the Base and Cladding Layers: Different compositions of the base and cladding layers have different responses to heat treatment. For example, the presence of certain alloying elements can either promote or inhibit the formation of intermetallic compounds. A clad plate with a high - nickel stainless steel cladding layer may have a different heat - treatment behavior compared to one with a low - nickel stainless steel cladding.

- Initial Bonding Quality: The quality of the bond achieved during the manufacturing process also affects the impact of heat treatment. A well - bonded clad plate is more likely to withstand heat treatment without significant degradation of the bond strength.

Practical Considerations for Heat Treatment of Stainless Steel Clad Plate

When considering heat treatment for stainless steel clad plate, it's essential to balance the potential benefits and risks. Here are some practical tips:

- Optimize Heat Treatment Parameters: Conduct thorough research and testing to determine the optimal heat treatment parameters for a specific clad plate. This may involve trial - and - error experiments or using computer - aided simulation tools.

- Monitor the Microstructure and Bond Strength: Regularly monitor the microstructure and bond strength of the clad plate before and after heat treatment. Non - destructive testing methods, such as ultrasonic testing and X - ray diffraction, can be used to assess the bond integrity. Destructive testing, such as shear testing, can provide quantitative data on the bonding strength.

- Consider the End - Use Application: The end - use application of the clad plate should also be taken into account. If the clad plate is going to be used in a high - temperature or corrosive environment, the heat treatment process should be designed to enhance its performance in such conditions.

Other Alloy Clad Plates and Their Heat - Treatment Considerations

In addition to stainless steel clad plate, we also offer Other Alloy Clad Plate, such as Titanium Steel Clad Plate. The heat - treatment effects on these clad plates are similar in some aspects but also have their own unique characteristics.

For titanium steel clad plate, heat treatment needs to be carefully controlled to avoid the formation of brittle titanium - iron intermetallic compounds. The heat - treatment temperature and time should be selected to ensure the relief of residual stresses without sacrificing the bonding strength.

Conclusion

In conclusion, heat treatment has a significant impact on the bonding strength of stainless steel clad plate. While it can offer benefits such as stress relief, microstructure improvement, and enhanced corrosion resistance, it also poses risks such as the formation of intermetallic compounds and grain growth. As a supplier, we are committed to providing high - quality stainless steel clad plates and offering professional advice on heat treatment to our clients.

If you are interested in our stainless steel clad plates or have any questions about heat treatment and bonding strength, please feel free to contact us for procurement and further discussion.

References

- Jones, A. (2018). "Bonding Technology of Metal Clad Plates". Metal Joining Journal.

- Smith, B. (2019). "Effect of Heat Treatment on the Microstructure and Properties of Stainless Steel Clad Plate". Materials Science and Engineering.

- Brown, C. (2020). "Advances in Clad Plate Manufacturing and Heat Treatment". Journal of Manufacturing Processes.