Pitting corrosion is a localized form of corrosion that can occur on metal surfaces, creating small holes or pits. This type of corrosion can be particularly problematic as it can lead to the failure of a metal component, even when the overall corrosion rate of the material seems relatively low. As a supplier of Titanium Steel Clad Plate, understanding the resistance of our product to pitting corrosion is of utmost importance.

Understanding Titanium Steel Clad Plate

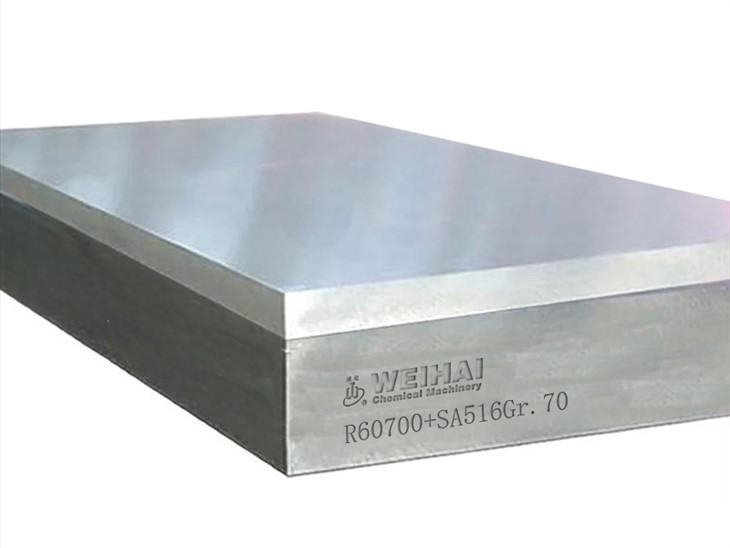

Titanium steel clad plate is a composite material that combines the excellent corrosion resistance of titanium with the high strength and low cost of steel. The titanium layer acts as a protective barrier, preventing the steel substrate from coming into contact with corrosive environments. This combination makes titanium steel clad plate an ideal choice for a wide range of applications, including chemical processing, marine engineering, and desalination plants.

Factors Affecting Pitting Corrosion Resistance

Several factors can influence the pitting corrosion resistance of titanium steel clad plate. These factors include the composition of the titanium layer, the surface finish of the material, the presence of impurities, and the environmental conditions in which the material is used.

- Composition of the Titanium Layer: The composition of the titanium layer plays a crucial role in determining its pitting corrosion resistance. Titanium alloys with higher levels of alloying elements, such as molybdenum and chromium, generally exhibit better pitting corrosion resistance than pure titanium. These alloying elements can form a more stable and protective oxide layer on the surface of the titanium, which helps to prevent the initiation and propagation of pits.

- Surface Finish: The surface finish of the titanium steel clad plate can also affect its pitting corrosion resistance. A smooth and clean surface is less likely to have defects or crevices where pitting corrosion can initiate. Therefore, proper surface preparation and finishing techniques, such as polishing and passivation, are essential to improve the pitting corrosion resistance of the material.

- Presence of Impurities: The presence of impurities in the titanium layer or the steel substrate can also reduce the pitting corrosion resistance of the clad plate. Impurities, such as sulfur and phosphorus, can react with the titanium or the steel to form compounds that are more susceptible to pitting corrosion. Therefore, it is important to use high-quality raw materials and to control the manufacturing process to minimize the presence of impurities.

- Environmental Conditions: The environmental conditions in which the titanium steel clad plate is used can also have a significant impact on its pitting corrosion resistance. Factors such as temperature, pH, chloride concentration, and the presence of other corrosive species can all affect the initiation and propagation of pits. For example, high temperatures and high chloride concentrations can increase the likelihood of pitting corrosion, while a neutral or slightly alkaline pH can help to inhibit it.

Testing the Pitting Corrosion Resistance of Titanium Steel Clad Plate

To ensure the pitting corrosion resistance of our titanium steel clad plate, we conduct a series of tests using various methods. One of the most common methods is the potentiodynamic polarization test, which measures the corrosion potential and the pitting potential of the material. The pitting potential is the minimum potential at which pitting corrosion can occur, and a higher pitting potential indicates better pitting corrosion resistance.

Another method is the immersion test, in which the clad plate is immersed in a corrosive solution for a specified period of time. After the immersion, the surface of the material is examined for the presence of pits, and the depth and density of the pits are measured. This test can provide valuable information about the long-term pitting corrosion resistance of the material.

Case Studies: Pitting Corrosion Resistance in Real-World Applications

In real-world applications, the pitting corrosion resistance of titanium steel clad plate has been proven to be excellent. For example, in a chemical processing plant, titanium steel clad plate was used to line the interior of a reaction vessel that was exposed to a highly corrosive environment containing hydrochloric acid and other aggressive chemicals. After several years of operation, the clad plate showed no signs of pitting corrosion, demonstrating its superior resistance to this type of corrosion.

In a marine engineering application, titanium steel clad plate was used to construct the hull of a ship. The ship was exposed to seawater, which is a highly corrosive environment due to its high chloride concentration. Despite the harsh conditions, the clad plate maintained its integrity and showed no signs of pitting corrosion, ensuring the long-term durability of the ship.

Comparison with Other Clad Plates

When compared to other types of clad plates, such as Copper Steel Clad Plate, titanium steel clad plate generally exhibits better pitting corrosion resistance. Copper is more susceptible to pitting corrosion in chloride-containing environments, especially at higher temperatures. In contrast, titanium forms a stable oxide layer that provides excellent protection against pitting corrosion, even in harsh environments.

Another type of clad plate is the Other Alloy Clad Plate, which can be made from various alloys. The pitting corrosion resistance of these clad plates depends on the specific alloy composition. However, in general, titanium steel clad plate offers a good balance of corrosion resistance, strength, and cost, making it a popular choice for many applications.

Conclusion and Call to Action

In conclusion, titanium steel clad plate is highly resistant to pitting corrosion, thanks to the excellent corrosion resistance of the titanium layer. However, to ensure the best performance, it is important to consider the factors that can affect pitting corrosion resistance, such as the composition of the titanium layer, the surface finish, the presence of impurities, and the environmental conditions.

If you are looking for a reliable and corrosion-resistant material for your next project, our titanium steel clad plate is an excellent choice. We have a wide range of products available, and our team of experts can help you select the right product for your specific needs. Contact us today to start a procurement discussion and find out how our titanium steel clad plate can benefit your project.

References

- Jones, D. A. (1992). Principles and Prevention of Corrosion. Prentice Hall.

- Uhlig, H. H., & Revie, R. W. (1985). Corrosion and Corrosion Control. Wiley.

- Fontana, M. G. (1986). Corrosion Engineering. McGraw-Hill.