Can explosive clad plates be machined?

As a supplier of explosive clad plates, I often encounter inquiries from customers about the machinability of these unique materials. Explosive clad plates are composite materials created by bonding two or more different metals together using explosive energy. This process results in a plate with the combined properties of the individual metals, offering enhanced corrosion resistance, strength, and other desirable characteristics. But the question remains: can these plates be machined?

Understanding Explosive Clad Plates

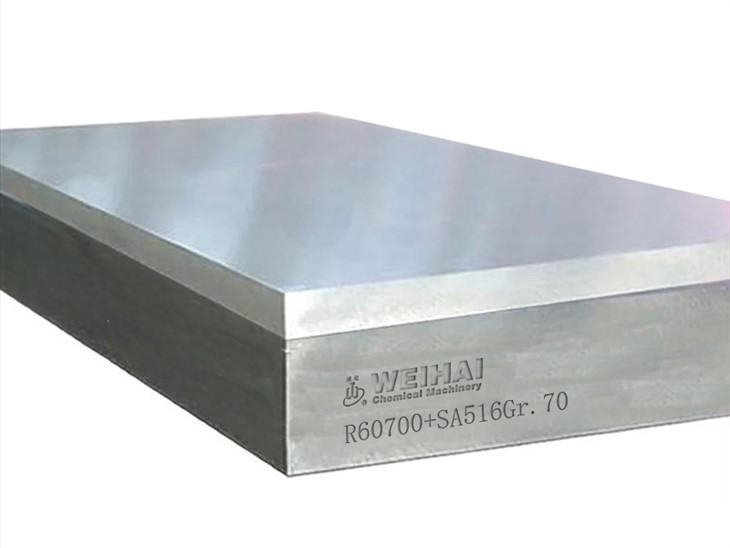

Before delving into the machinability of explosive clad plates, it's essential to understand their composition and structure. Explosive clad plates typically consist of a base metal and a cladding metal. The base metal provides the structural strength, while the cladding metal offers specific surface properties such as corrosion resistance or wear resistance. The bonding between the two metals is achieved through a high - energy explosive process, which creates a metallurgical bond at the interface.

There are different types of explosive clad plates available, such as Two Sides Clad Plate, Stainless Steel Clad Plate, and Other Alloy Clad Plate. Each type has its own unique properties and applications, which can also influence the machining process.

Machining Considerations

The answer to whether explosive clad plates can be machined is yes, but it comes with certain challenges and considerations.

1. Material Properties

The different metals in the clad plate have distinct mechanical and physical properties. For example, the base metal might be a high - strength carbon steel, while the cladding could be a corrosion - resistant stainless steel. These differences in hardness, ductility, and thermal conductivity can affect the machining process. Harder materials require more powerful cutting tools and slower cutting speeds to avoid tool wear and damage.

2. Bond Integrity

Maintaining the integrity of the bond between the base and cladding metals is crucial during machining. Excessive heat or mechanical stress can cause delamination at the bond interface, which compromises the performance of the clad plate. Therefore, it's necessary to select appropriate machining parameters and techniques to minimize the risk of bond failure.

3. Cutting Tools

Selecting the right cutting tools is essential for successful machining of explosive clad plates. Carbide tools are often preferred due to their high hardness and wear resistance. However, the tool geometry also needs to be carefully designed to suit the specific materials being machined. For example, a tool with a sharp cutting edge can reduce the cutting force and heat generation, which is beneficial for preserving the bond integrity.

Machining Techniques

There are several machining techniques that can be used for explosive clad plates, each with its own advantages and limitations.

1. Turning

Turning is a common machining process used to produce cylindrical parts. When turning explosive clad plates, it's important to start with a low cutting speed and feed rate to avoid excessive heat generation. Using a coolant can also help to dissipate heat and improve the surface finish. Additionally, the cutting tool should be sharp and properly aligned to ensure a smooth cutting operation.

2. Milling

Milling is another widely used machining process for creating flat surfaces, slots, and contours. In milling explosive clad plates, the cutter selection is crucial. End mills with multiple flutes can provide a more stable cutting process and better chip evacuation. Similar to turning, a coolant should be used to control the temperature and prevent bond failure.

3. Drilling

Drilling holes in explosive clad plates requires special attention. The drill bit should be sharp and made of a suitable material, such as high - speed steel or carbide. It's recommended to use a peck - drilling technique, which involves periodically retracting the drill bit to clear the chips. This helps to prevent chip clogging and reduces the risk of overheating.

Case Studies

To illustrate the practical aspects of machining explosive clad plates, let's look at some case studies.

Case 1: Machining a Stainless Steel Clad Plate for a Chemical Processing Vessel

A customer required a stainless steel clad plate to be machined into a chemical processing vessel. The base metal was carbon steel, and the cladding was stainless steel. By using carbide cutting tools and appropriate machining parameters, the plate was successfully machined without any delamination at the bond interface. The vessel met all the required specifications and has been in service for several years without any issues.

Case 2: Turning a Two Sides Clad Plate for a Shaft Application

In another case, a two - sides clad plate was turned into a shaft. The machining process was carefully planned to ensure that the bond between the base and cladding metals remained intact. By using a coolant and a sharp cutting tool, the shaft was machined to the desired dimensions with a good surface finish.

Quality Control

Quality control is an integral part of the machining process for explosive clad plates. After machining, the parts should be inspected for any signs of bond failure, such as delamination or cracks. Non - destructive testing methods, such as ultrasonic testing, can be used to detect internal defects in the bond. Additionally, the surface finish and dimensional accuracy should be checked to ensure that the parts meet the required specifications.

Conclusion

In conclusion, explosive clad plates can be machined, but it requires careful consideration of the material properties, bond integrity, and appropriate machining techniques. With the right approach, these plates can be successfully machined into a wide range of products for various industries, including chemical processing, oil and gas, and power generation.

If you are interested in our explosive clad plates and have any machining requirements, we would be more than happy to discuss your needs. Our team of experts can provide you with detailed technical support and advice to ensure that you get the best - quality products and machining services. Contact us to start a procurement discussion and discover how our explosive clad plates can meet your specific applications.

References

- ASM Handbook, Volume 16: Machining, ASM International.

- "Machining of Metal Matrix Composites", by R. Komanduri and T. S. Bhattacharyya.

- "Advanced Machining Processes: Nontraditional and Hybrid Processes", by P. K. Jain.