Hey there! As a supplier of Nickel-base Steel Clad Plate, I often get asked about the tempering process for this amazing material. So, I thought I'd take a few minutes to break it down for you.

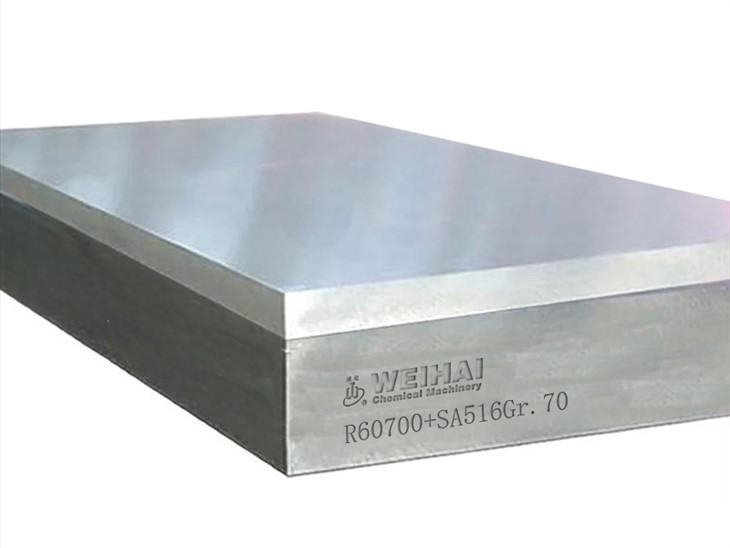

First off, let's talk a bit about what Nickel-base Steel Clad Plate is. It's a composite material that combines the corrosion resistance and high-temperature performance of nickel-based alloys with the strength and low cost of carbon steel. This makes it a popular choice in a wide range of industries, from chemical processing to power generation.

Now, onto the tempering process. Tempering is a heat treatment process that's used to improve the mechanical properties of metals, including Nickel-base Steel Clad Plate. The main goal of tempering is to reduce the hardness and brittleness that can result from quenching, while also increasing the toughness and ductility of the material.

The tempering process for Nickel-base Steel Clad Plate typically involves heating the material to a specific temperature, holding it at that temperature for a certain period of time, and then cooling it down slowly. The exact temperature and time depend on a variety of factors, such as the composition of the nickel-based alloy, the thickness of the clad layer, and the desired mechanical properties.

One of the key benefits of tempering Nickel-base Steel Clad Plate is that it can improve the bond between the clad layer and the base steel. During the tempering process, the atoms in the two materials diffuse across the interface, creating a strong and durable bond. This helps to prevent delamination and other forms of failure, which can be a major concern in applications where the material is exposed to high stresses or harsh environments.

Another advantage of tempering is that it can enhance the corrosion resistance of the clad layer. By reducing the internal stresses and improving the microstructure of the material, tempering can make it more resistant to corrosion and other forms of degradation. This is especially important in applications where the material is exposed to corrosive chemicals or high temperatures.

So, how do we go about tempering Nickel-base Steel Clad Plate? Well, the first step is to preheat the material to a temperature that's slightly below the tempering temperature. This helps to ensure that the material heats up evenly and reduces the risk of thermal shock. Once the material is preheated, we transfer it to a furnace and heat it up to the tempering temperature. We then hold the material at that temperature for a specified period of time, typically anywhere from a few hours to several days, depending on the size and thickness of the plate.

After the holding period is over, we slowly cool the material down to room temperature. This is usually done by turning off the furnace and allowing the material to cool naturally inside the furnace. In some cases, we may use a controlled cooling rate to further improve the mechanical properties of the material.

It's important to note that the tempering process is just one step in the manufacturing of Nickel-base Steel Clad Plate. Before tempering, the plate is typically subjected to a variety of other processes, such as rolling, welding, and heat treatment, to ensure that it meets the required specifications. And after tempering, the plate may undergo additional processing, such as machining, grinding, or coating, depending on the specific application.

At our company, we take great pride in our ability to produce high-quality Nickel-base Steel Clad Plate. We use state-of-the-art equipment and techniques to ensure that our plates are tempered to the exact specifications required by our customers. And we have a team of experienced engineers and technicians who are dedicated to providing the best possible service and support.

If you're in the market for Nickel-base Steel Clad Plate, or if you have any questions about the tempering process or our products, please don't hesitate to [contact us for procurement and negotiation]. We'd be happy to help you find the right solution for your needs.

In addition to Nickel-base Steel Clad Plate, we also offer a wide range of other alloy clad plates, such as Other Alloy Clad Plate and Titanium Steel Clad Plate. These materials offer similar benefits to Nickel-base Steel Clad Plate, but with different properties and applications. So, if you're interested in learning more about these products, be sure to check out our website or give us a call.

In conclusion, the tempering process is an important step in the manufacturing of Nickel-base Steel Clad Plate. By improving the bond between the clad layer and the base steel, enhancing the corrosion resistance, and improving the mechanical properties, tempering can make the material more reliable and durable in a wide range of applications. If you have any questions or need more information, please don't hesitate to [contact us for procurement and negotiation]. We're here to help you get the most out of your Nickel-base Steel Clad Plate.

References:

- ASM Handbook, Volume 4: Heat Treating

- Welding Handbook, Volume 2: Welding Processes

- Corrosion Resistance of Nickel and Nickel Alloys, ASM International