Nickel-base steel clad plates are a remarkable class of composite materials that combine the excellent properties of nickel-base alloys with the structural strength of steel. As a leading supplier of nickel-base steel clad plates, I am often asked about their heat resistance. In this blog post, I will delve into the heat resistance of nickel-base steel clad plates, exploring the factors that influence it and the applications where this property is crucial.

Understanding Nickel-base Steel Clad Plates

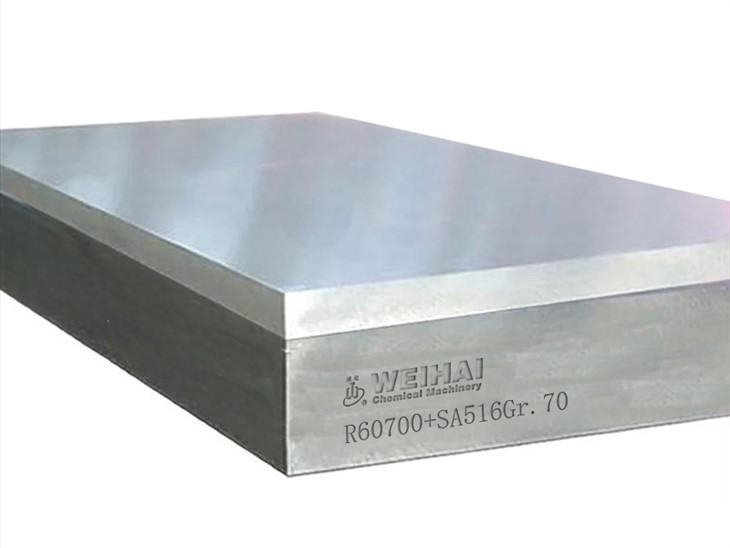

Before we discuss heat resistance, let's briefly understand what nickel-base steel clad plates are. These plates are made by bonding a layer of nickel-base alloy to a steel substrate. The bonding process can be achieved through various methods, such as explosive welding, roll bonding, or hot isostatic pressing. The resulting composite material combines the corrosion resistance, high-temperature strength, and other desirable properties of the nickel-base alloy with the mechanical strength and cost-effectiveness of steel.

Factors Affecting Heat Resistance

The heat resistance of nickel-base steel clad plates is influenced by several factors, including the composition of the nickel-base alloy, the thickness of the clad layer, and the bonding quality between the clad layer and the steel substrate.

Composition of the Nickel-base Alloy

The composition of the nickel-base alloy plays a crucial role in determining the heat resistance of the clad plate. Nickel-base alloys typically contain a high percentage of nickel, along with other elements such as chromium, molybdenum, and iron. These elements contribute to the alloy's ability to resist oxidation, corrosion, and creep at high temperatures.

For example, alloys with a high chromium content form a protective oxide layer on the surface when exposed to high temperatures, which helps to prevent further oxidation and corrosion. Molybdenum and other refractory elements enhance the alloy's strength and creep resistance at elevated temperatures.

Thickness of the Clad Layer

The thickness of the clad layer also affects the heat resistance of the nickel-base steel clad plate. A thicker clad layer provides more protection against high temperatures and corrosion. However, increasing the thickness of the clad layer also increases the cost of the plate. Therefore, the thickness of the clad layer needs to be carefully selected based on the specific application requirements.

Bonding Quality

The bonding quality between the clad layer and the steel substrate is another important factor that influences the heat resistance of the clad plate. A strong and uniform bond ensures that the clad layer remains attached to the steel substrate even under high-temperature conditions. Poor bonding can lead to delamination, which can compromise the performance of the clad plate.

Heat Resistance Performance

Nickel-base steel clad plates exhibit excellent heat resistance properties, making them suitable for a wide range of high-temperature applications.

Oxidation Resistance

One of the key heat resistance properties of nickel-base steel clad plates is their oxidation resistance. At high temperatures, metals tend to react with oxygen in the air to form oxides. These oxides can cause the metal to corrode and lose its strength. Nickel-base alloys, however, have a high resistance to oxidation due to the formation of a protective oxide layer on the surface.

This oxide layer acts as a barrier, preventing further oxidation of the underlying metal. As a result, nickel-base steel clad plates can withstand prolonged exposure to high temperatures in oxidizing environments without significant degradation.

Corrosion Resistance

In addition to oxidation resistance, nickel-base steel clad plates also offer excellent corrosion resistance at high temperatures. They can resist corrosion in a variety of aggressive environments, including those containing acids, alkalis, and salts.

This corrosion resistance is particularly important in applications where the clad plate is exposed to high-temperature corrosive media, such as in chemical processing, power generation, and petrochemical industries.

Creep Resistance

Creep is the gradual deformation of a material under constant stress at high temperatures. Nickel-base steel clad plates have good creep resistance, which means they can maintain their shape and strength even when subjected to long-term high-temperature loading.

This property is essential in applications where the clad plate is used in structures that are subjected to high temperatures and mechanical stresses, such as in aerospace, automotive, and nuclear industries.

Applications of Nickel-base Steel Clad Plates in High-temperature Environments

The excellent heat resistance of nickel-base steel clad plates makes them ideal for a wide range of high-temperature applications.

Chemical Processing

In the chemical processing industry, nickel-base steel clad plates are used in equipment such as reactors, heat exchangers, and storage tanks. These plates can withstand the high temperatures and corrosive chemicals involved in chemical reactions, ensuring the safe and efficient operation of the equipment.

Power Generation

In power generation plants, nickel-base steel clad plates are used in boilers, turbines, and other high-temperature components. They can resist the high temperatures and pressures generated during the power generation process, improving the reliability and efficiency of the power plant.

Petrochemical Industry

The petrochemical industry also relies on nickel-base steel clad plates for various applications, such as in refineries, pipelines, and storage facilities. These plates can withstand the high temperatures and corrosive hydrocarbons present in the petrochemical processes, ensuring the integrity of the equipment.

Comparison with Other Clad Plates

When considering heat resistance, it's also useful to compare nickel-base steel clad plates with other types of clad plates. Other Alloy Clad Plate offer different properties depending on the specific alloys used. For instance, Titanium Steel Clad Plate are known for their high strength-to-weight ratio and excellent corrosion resistance, but their heat resistance may not be as high as that of nickel-base steel clad plates in extremely high-temperature applications. Stainless Steel Clad Plate are also widely used, but they may not offer the same level of oxidation and corrosion resistance at very high temperatures as nickel-base steel clad plates.

Conclusion

In conclusion, nickel-base steel clad plates offer excellent heat resistance due to the unique properties of the nickel-base alloy and the strong bond with the steel substrate. Their oxidation resistance, corrosion resistance, and creep resistance make them suitable for a wide range of high-temperature applications in various industries.

If you are in need of high-quality nickel-base steel clad plates for your high-temperature applications, I encourage you to contact us for a detailed discussion. Our team of experts can help you select the right clad plate based on your specific requirements and provide you with the best solutions for your project.

References

- ASM Handbook Volume 13C: Corrosion: Stainless Steels. ASM International.

- Nickel and Nickel Alloys: Properties and Applications. ASM International.

- Welding of Nickel and High-Nickel Alloys. American Welding Society.