What are the design considerations when using Two Sides Clad Plate?

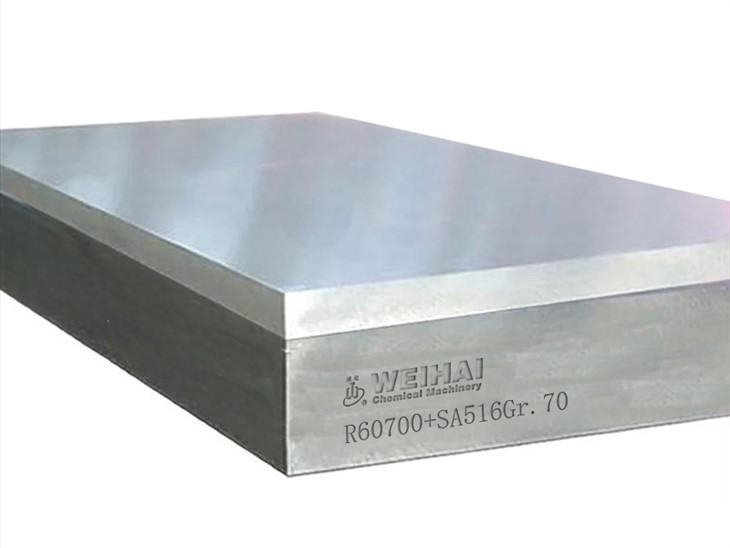

As a supplier of Two Sides Clad Plate, I have witnessed firsthand the growing demand for this versatile material across various industries. Two Sides Clad Plate offers a unique combination of properties, making it an ideal choice for applications where corrosion resistance, high strength, and cost - effectiveness are required. In this blog post, I will discuss the key design considerations when using Two Sides Clad Plate.

Material Selection

The first and most crucial design consideration is the selection of the base and cladding materials. The base material provides the structural strength of the plate, while the cladding materials offer specific surface properties such as corrosion resistance, wear resistance, or heat resistance.

For applications in corrosive environments, stainless steel is a popular choice for the cladding material. Stainless Steel Clad Plate can effectively protect the base material from corrosion, extending the service life of the structure. Common base materials include carbon steel, which is cost - effective and has good mechanical properties.

In some cases, other alloy materials may be used as the cladding. Other Alloy Clad Plate can offer specialized properties such as high - temperature resistance or enhanced electrical conductivity. When selecting the materials, it is essential to consider the compatibility between the base and cladding materials. Different materials have different thermal expansion coefficients, and if they are not compatible, it may lead to delamination or cracking during thermal cycling or mechanical loading.

Thickness Ratio

The thickness ratio of the base material to the cladding material is another important design factor. This ratio affects the overall performance and cost of the Two Sides Clad Plate. A higher cladding thickness provides better surface properties but increases the cost of the plate. On the other hand, a lower cladding thickness may reduce the cost but may not provide sufficient protection or performance.

The thickness ratio should be determined based on the specific application requirements. For example, in applications where corrosion resistance is the primary concern, a relatively thicker cladding may be required. However, in applications where structural strength is more critical, a thinner cladding can be used while still maintaining the necessary surface properties.

Bonding Method

The bonding method used to join the base and cladding materials has a significant impact on the quality and performance of the Two Sides Clad Plate. There are several bonding methods available, including explosive bonding, roll bonding, and diffusion bonding.

Explosive bonding is a widely used method for producing Two Sides Clad Plate. It offers a strong metallurgical bond between the base and cladding materials, which can withstand high - stress applications. This method is suitable for a wide range of material combinations and can produce large - size clad plates. Two Sides Clad Plate produced by explosive bonding has excellent bond strength and integrity.

Roll bonding involves passing the base and cladding materials through a rolling mill to create a bond. This method is suitable for producing clad plates with relatively thin claddings and is more suitable for continuous production. Diffusion bonding, on the other hand, uses heat and pressure to promote atomic diffusion between the two materials, creating a solid - state bond. Each bonding method has its advantages and limitations, and the choice of bonding method should be based on the material combination, plate size, and application requirements.

Design for Fabrication

When using Two Sides Clad Plate, it is essential to consider the fabrication process. The plate may need to be cut, welded, or formed during the manufacturing of the final product. Special attention should be paid to the welding process, as welding can affect the bond between the base and cladding materials and the corrosion resistance of the cladding.

Proper welding procedures should be developed to ensure that the weld quality meets the requirements. This may involve using appropriate welding consumables, pre - heating and post - heating treatments, and controlling the welding parameters. Additionally, the cutting and forming processes should be designed to minimize the damage to the cladding and the bond between the materials.

Application - Specific Considerations

Different applications have different requirements for Two Sides Clad Plate. In the chemical industry, for example, the plate needs to have excellent corrosion resistance to withstand the harsh chemical environments. In the power generation industry, high - temperature resistance and mechanical strength are often the key requirements.

In the food processing industry, the cladding material should be non - toxic and easy to clean to meet the hygiene standards. Therefore, when designing with Two Sides Clad Plate, it is necessary to fully understand the specific requirements of the application and select the appropriate materials, thickness ratios, and bonding methods accordingly.

Quality Control

Quality control is an integral part of the design and production of Two Sides Clad Plate. Non - destructive testing methods such as ultrasonic testing, X - ray testing, and magnetic particle testing can be used to detect any defects in the bond between the base and cladding materials. Visual inspection can also be carried out to check for surface defects such as cracks, delamination, or uneven cladding thickness.

Regular quality control checks should be performed during the production process to ensure that the Two Sides Clad Plate meets the required standards. This includes testing the mechanical properties, corrosion resistance, and bond strength of the plate.

In conclusion, using Two Sides Clad Plate requires careful consideration of multiple factors, including material selection, thickness ratio, bonding method, fabrication design, application - specific requirements, and quality control. By taking these design considerations into account, we can ensure that the Two Sides Clad Plate meets the performance requirements of the application while also being cost - effective.

If you are interested in our Two Sides Clad Plate products or have any questions regarding the design and application of these plates, please feel free to contact us for further discussion and procurement negotiation. We are committed to providing high - quality products and professional technical support to meet your specific needs.

References

- ASM Handbook Volume 6: Welding, Brazing, and Soldering. ASM International.

- "Clad Metals: Production, Properties, and Applications" by R. E. Smallman and R. J. Bishop.

- Standards and specifications related to clad plates issued by relevant national and international organizations.