Hey there! As a supplier of Titanium Steel Clad Plate, I've seen firsthand how important it is to improve the corrosion resistance of these plates. In this blog, I'll share some practical tips and insights on how to do just that.

Understanding Titanium Steel Clad Plate

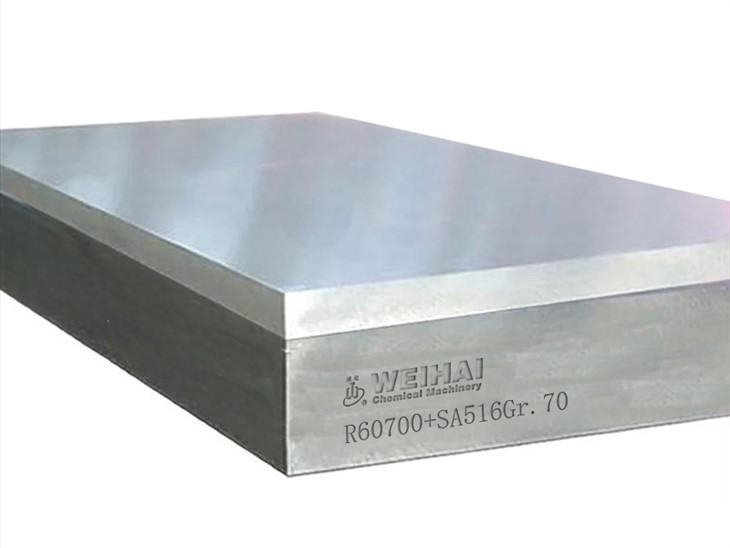

First off, let's quickly go over what Titanium Steel Clad Plate is. It's a composite material that combines the excellent corrosion resistance of titanium with the high strength and affordability of steel. This makes it a popular choice in various industries, such as chemical processing, desalination plants, and marine applications.

The way it's made is pretty cool. Usually, a layer of titanium is bonded to a steel substrate through processes like explosive welding or hot rolling. This creates a strong and durable material that can withstand harsh environments. But even though it's already quite resistant to corrosion, there are still ways to make it even better.

Factors Affecting Corrosion Resistance

Before we dive into the solutions, it's important to understand the factors that can affect the corrosion resistance of Titanium Steel Clad Plate.

- Environment: The type of environment the plate is exposed to plays a huge role. For example, in a marine environment, the high salt content in the air and water can accelerate corrosion. In a chemical processing plant, exposure to acids, alkalis, and other corrosive chemicals can also cause problems.

- Surface Condition: The surface finish of the plate can impact its corrosion resistance. A rough surface is more likely to trap moisture and corrosive agents, while a smooth surface is easier to clean and less prone to corrosion.

- Bond Quality: The quality of the bond between the titanium layer and the steel substrate is crucial. If the bond is weak or there are defects in the bonding process, it can lead to delamination and corrosion at the interface.

Ways to Improve Corrosion Resistance

Surface Treatment

- Polishing: One of the simplest ways to improve corrosion resistance is to polish the surface of the Titanium Steel Clad Plate. Polishing can remove surface irregularities and create a smooth, reflective surface. This not only makes the plate look better but also reduces the surface area available for corrosion to occur. You can use mechanical polishing methods, such as grinding and buffing, to achieve a high - quality finish.

- Passivation: Passivation is a chemical treatment process that forms a thin, protective oxide layer on the surface of the titanium. This oxide layer acts as a barrier, preventing oxygen and other corrosive agents from reaching the underlying metal. To passivate a Titanium Steel Clad Plate, you can immerse it in a solution of nitric acid and hydrogen peroxide. The concentration of the solution and the immersion time need to be carefully controlled to ensure proper passivation.

Coating Application

- Organic Coatings: Applying an organic coating, such as epoxy or polyurethane, can provide an additional layer of protection against corrosion. These coatings can fill in any small pores or defects on the surface of the plate and prevent moisture and corrosive agents from reaching the metal. Before applying the coating, the surface of the plate needs to be properly cleaned and prepared to ensure good adhesion.

- Ceramic Coatings: Ceramic coatings are another option for improving corrosion resistance. They have excellent chemical stability and can withstand high temperatures and harsh environments. Ceramic coatings can be applied using techniques like thermal spraying or chemical vapor deposition. However, they are usually more expensive and require specialized equipment for application.

Proper Installation and Maintenance

- Installation: During installation, it's important to ensure that the Titanium Steel Clad Plate is properly supported and protected. Avoid scratching or damaging the surface of the plate, as this can compromise its corrosion resistance. Also, make sure that the plate is installed in a way that allows for proper drainage, so that water and other corrosive liquids don't accumulate on the surface.

- Maintenance: Regular maintenance is essential for keeping the plate in good condition. This includes cleaning the plate regularly to remove dirt, debris, and corrosive agents. You can use mild detergents and soft brushes to clean the surface. Inspect the plate periodically for signs of corrosion, such as rust spots or delamination. If any problems are detected, take appropriate measures to address them immediately.

Alloy Selection

- Titanium Alloy: Choosing the right titanium alloy can significantly improve the corrosion resistance of the Titanium Steel Clad Plate. Different titanium alloys have different levels of corrosion resistance depending on their chemical composition. For example, titanium alloys with a high content of molybdenum and nickel are more resistant to corrosion in acidic environments.

- Steel Substrate: The type of steel used as the substrate also matters. Stainless steel is often a good choice because it has its own inherent corrosion resistance. You can check out Stainless Steel Clad Plate for more information on using stainless steel in clad plates.

Other Considerations

- Design Considerations: When designing a structure or equipment using Titanium Steel Clad Plate, consider the potential for corrosion. Avoid creating areas where water or corrosive agents can accumulate, such as crevices or pockets. Use proper drainage and ventilation systems to keep the plate dry and well - ventilated.

- Testing and Monitoring: Regularly test and monitor the corrosion resistance of the Titanium Steel Clad Plate. You can use techniques like electrochemical testing to measure the corrosion rate and detect any early signs of corrosion. This allows you to take preventive measures before serious damage occurs.

Conclusion

Improving the corrosion resistance of Titanium Steel Clad Plate is crucial for ensuring its long - term performance and durability. By understanding the factors that affect corrosion and implementing the right strategies, such as surface treatment, coating application, proper installation and maintenance, and alloy selection, you can significantly enhance the corrosion resistance of these plates.

If you're interested in purchasing Titanium Steel Clad Plate or need more information on improving its corrosion resistance, feel free to reach out for a purchase negotiation. We also offer Other Alloy Clad Plate if you're looking for different options. You can find more details about our Titanium Steel Clad Plate on our website.

References

- Jones, D. A. (1992). Principles and Prevention of Corrosion. Prentice Hall.

- Uhlig, H. H., & Revie, R. W. (1985). Corrosion and Corrosion Control: An Introduction to Corrosion Science and Engineering. Wiley - Interscience.