Hey there! I'm a supplier of Copper Steel Clad Plate, and today I wanna chat about how the creep behavior of this awesome material affects its long - term performance.

First off, let's get a basic understanding of what creep is. Creep is the slow, time - dependent deformation that materials undergo under a constant load at elevated temperatures. For Copper Steel Clad Plate, this behavior can have a big impact on its long - term use.

Understanding the Structure of Copper Steel Clad Plate

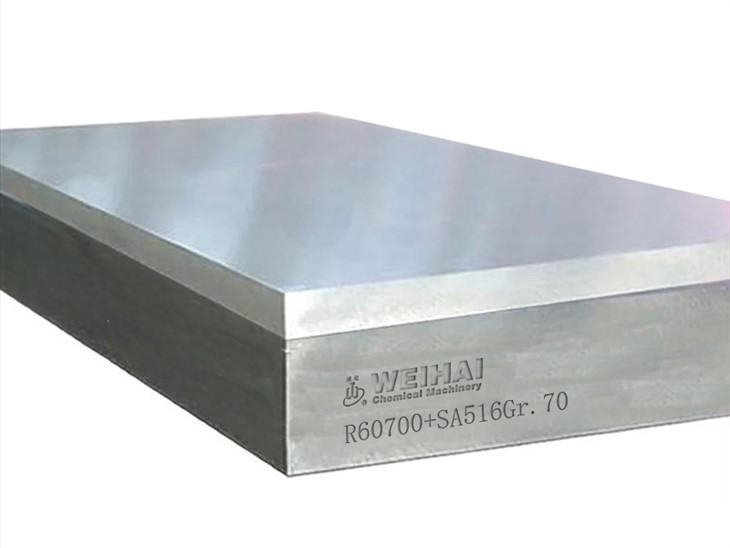

Copper Steel Clad Plate is a composite material made by bonding a layer of copper to a layer of steel. The copper layer usually offers good electrical and thermal conductivity, while the steel layer provides strength and durability. But when it comes to creep, the different properties of these two materials can lead to some interesting effects.

The copper layer in the clad plate has a relatively low melting point compared to steel. At high temperatures, copper starts to soften more easily. This means that under a constant load, the copper layer may start to deform at a faster rate than the steel layer. This differential deformation can cause stress concentrations at the interface between the copper and the steel.

Impact on Bonding

One of the most critical aspects affected by creep is the bonding between the copper and the steel layers. The bond between these two materials is crucial for the overall performance of the clad plate. When the copper layer creeps, it can put extra stress on the bond. Over time, this stress can lead to bond degradation.

If the bond between the copper and steel weakens, it can result in delamination. Delamination is a serious issue as it can significantly reduce the mechanical and functional properties of the clad plate. For example, if the plate is being used in an electrical application, delamination can increase electrical resistance, leading to energy losses and potential overheating.

Effect on Dimensional Stability

Creep also affects the dimensional stability of the Copper Steel Clad Plate. As the copper layer deforms due to creep, the overall dimensions of the plate can change. This is a big deal, especially in applications where precise dimensions are required.

Let's say you're using the clad plate in a manufacturing process where it needs to fit into a specific mold or assembly. If the plate creeps and changes its dimensions, it may no longer fit properly. This can lead to production delays, increased costs, and even product failures.

Influence on Mechanical Properties

The mechanical properties of the Copper Steel Clad Plate are also affected by creep. As the copper layer deforms, the load - bearing capacity of the plate can change. The plate may become more prone to bending, cracking, or other forms of mechanical failure.

In high - stress applications, such as in structural components or machinery parts, this reduction in mechanical properties can be extremely dangerous. A cracked or failed clad plate can lead to equipment breakdowns, safety hazards, and costly repairs.

Comparing with Other Clad Plates

It's interesting to compare the creep behavior of Copper Steel Clad Plate with other types of clad plates. For example, Stainless Steel Clad Plate has a different set of properties. Stainless steel has a higher melting point and better creep resistance compared to copper. So, in high - temperature applications, stainless steel clad plates may be more stable in terms of creep.

Titanium Steel Clad Plate is another option. Titanium is known for its excellent strength - to - weight ratio and high - temperature performance. The creep behavior of titanium steel clad plates may be different from that of copper steel clad plates, depending on the specific conditions.

There are also Other Alloy Clad Plate options available in the market. Each of these has its own unique set of properties and creep characteristics.

Mitigating the Effects of Creep

So, what can we do to mitigate the effects of creep on Copper Steel Clad Plate? One approach is to carefully select the materials and the manufacturing process. Using high - quality copper and steel with good creep resistance can make a big difference.

The manufacturing process also plays a crucial role. Proper heat treatment and bonding techniques can enhance the bond strength between the copper and steel layers, reducing the risk of delamination due to creep.

Another strategy is to operate the clad plate within its recommended temperature and load limits. By keeping the temperature and load within a safe range, the rate of creep can be significantly reduced.

Long - Term Performance in Different Applications

In electrical applications, the long - term performance of the Copper Steel Clad Plate is closely related to its electrical conductivity. As mentioned earlier, creep - induced delamination can increase electrical resistance. This can lead to power losses and reduced efficiency over time.

In heat exchanger applications, the ability of the clad plate to transfer heat efficiently is essential. Creep can affect the contact between the plate and the fluid, reducing the heat transfer coefficient. This can result in decreased cooling or heating performance.

In mechanical applications, such as in automotive or aerospace components, the dimensional stability and mechanical strength of the clad plate are crucial. Creep can cause parts to wear out faster, leading to increased maintenance and replacement costs.

Conclusion

In conclusion, the creep behavior of Copper Steel Clad Plate has a significant impact on its long - term performance. It affects the bonding between the copper and steel layers, dimensional stability, mechanical properties, and performance in different applications.

As a supplier, I understand the importance of providing high - quality clad plates that can withstand the challenges of creep. By carefully selecting materials, using advanced manufacturing techniques, and providing proper guidance on usage, we can ensure that our customers get the best performance from our Copper Steel Clad Plate.

If you're interested in learning more about our Copper Steel Clad Plate or other clad plate products, or if you're looking to start a procurement process, feel free to reach out. We're here to answer your questions and help you find the right solution for your needs.

References

- ASM Handbook Volume 2: Properties and Selection: Nonferrous Alloys and Special - Purpose Materials.

- "Creep in Metals and Alloys" by B. Wilshire and R. W. Evans.

- Research papers on the performance of composite materials in high - temperature environments.